Welcome! Please feel free to subscribe to the newsletter to get studio updates and projects from the archives straight to your inbox.

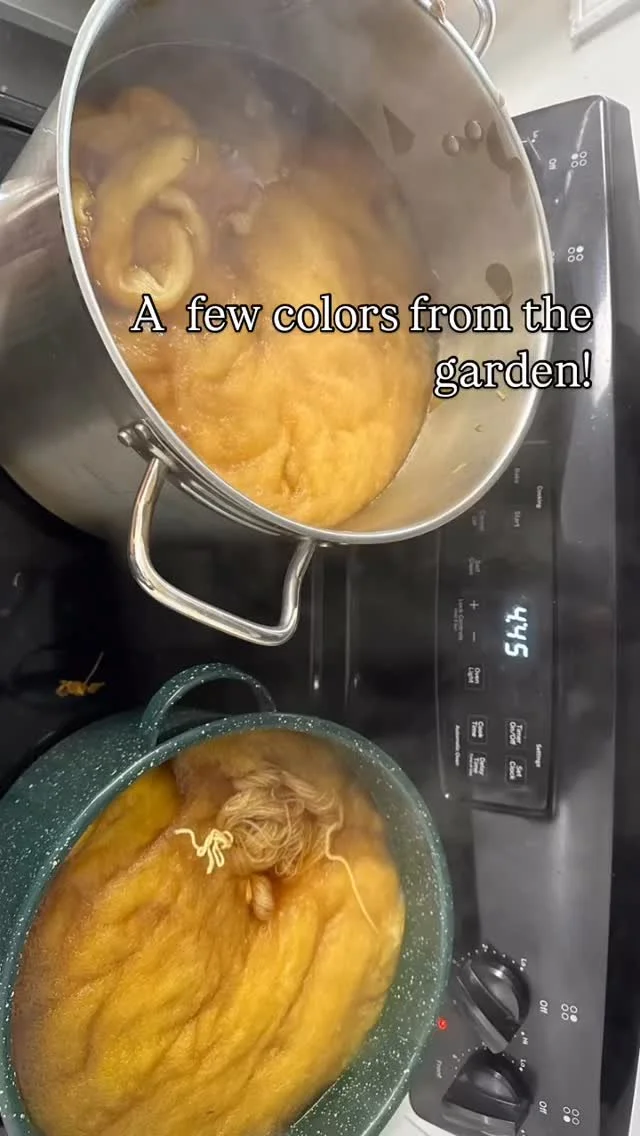

Weft Magic

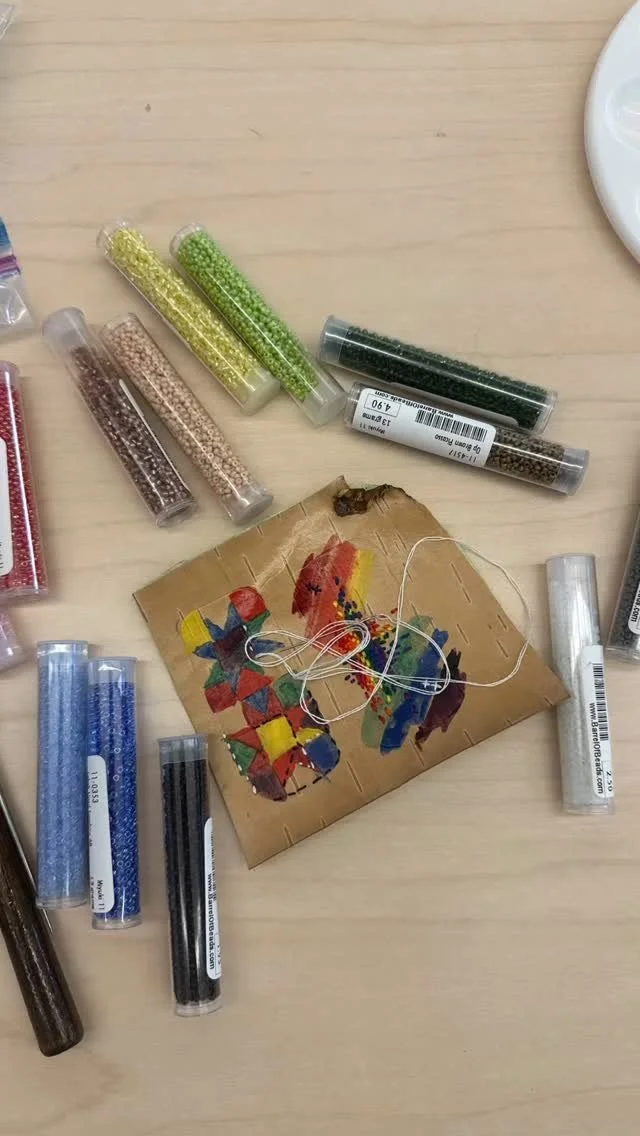

The 8 of Cups, my first Tarot-inspired warp - is more than half threaded, which means we're getting so close to weaving I can almost taste it! These skeins of Seacell (and mini skein of handspun Sea Island Cotton) are the first weft; it will be a (deeply meaningful) personal piece for me.

You may notice that these skeins are not quite uniformly dyed. This is intentional. I've been experimenting with a dye technique that leads to this sort of beautiful inconsistency. Usually when I dye weft for a wrap, I want all the skeins to be as similar as possible so that there are no noticeable differences through the length of the piece. I figured a personal piece then was the best place to experiment with this technique on a weft, though I plan to use it more in the future on warps! I'm excited to see just how it weaves up.

When I lay out the yarn to be dyed, I lay the skeins out next to each other so that they create a sort of canvas. Then I use the dye to paint symbols, or words, or images onto that canvas. Then I fill in the blank space with the (other) colors for the yarn. This imbeds the meaning into the threads in a far-below-the-surface kind of way. In this instance I painted triskeles and moon sigils into the yarn. The images themselves will never be visible in the final piece of cloth, but the meaning is deep in every thread.

With the impending federal regulations governing baby wraps effective early next year, I'll be launching a new babywrap brand with a couple of dear colleagues. Our tagline for Cauldron & Cloth - chatter launching soon, keep an eye out! - is "woven with love and magic" and this is one of the ways I weave with magic. <3

Sugar Plum Fairy: start to finish

Weaving is a slow craft. Intentional, meticulous, time consuming. It can be a month or three (or more!) between when yarn is chosen and/or dyed for a project and when the final piece is pulled off the loom. I share the progress over in the Chatter group and on Instagram; but if you're not always checking in and following along you may not see the whole process come together. I've had a few requests to collate the whole process into one blog post so you can sit down and see it all in one place. I've tried to do that here for Sugar Plum Fairy:

Sugar Plum Fairy was 14 Mile Farm's 2016 midwinter holiday exclusive this year. Inspired by the magic of the Nutcracker Suite and the way this festive ballet ushers in the midwinter holidays every year, Sugar Plum Fairy is an homage to the character who enchanted my childhood with visions of otherworldly winter landscapes and whose role requires technical prowess and artistry from the dancer that continues to inspire me today.

I hand dyed the cotton weft yarn in skeins in seven shades of purple, violet, and blue. Each of the dozen or so skeins was slightly different, with a different combination of these colors. I then warped from the balled skeins, mixing the variegate yarn across the whole width of the project.

This particular warp I warped front to back, meaning that the individual threads (over 700 of them!) first go through the slots of the reed - pictured above - then are threaded through the heddles. The threading pattern is what allows for the creation of the pattern in the cloth. The step of threading the heddles requires care and attention. I prefer to do it methodically and meticulously (even if that slows down an already slow process) to avoid errors. Errors at this stage compound on each other and just require time-consuming fixing later. Once threaded, the warp is tied on and wound onto the back beam. Below you can see I'm passing the warp through a set of dowels as a tensioning device. The dowels have the pleasant side effect of making for excellent photography props. Once the entire length of the warp is wound on, it is time to tie on in front and then finally to weave!

I love the way that this particular dye method/process creates a beautifully blended painted effect. As each individual warp thread changes color along its length at its own interval, no spot along the length of the warp is precisely the same as colors fade in and out and back again beside each other, but the whole cloth takes on a cohesive almost impressionist visual sense.

One of the beauties of weaving long warps that allow for multiple pieces off of one warp is the way that I'm able to play with wefts: experimenting with different colors, fibers, and dye techniques. The first weft on Sugar Plum Fairy was a merino/silk/stellina(sparkle) yarn - which I totally adore as weft. I'll admit to having been ever so slightly leery of sparkle yarn - my personal tendency being towards earthy and rich - but I thought it would be perfect to capture the glint of snow. Living in Alaska where winters bring an abundance of snow and an abundance of darkness, I have often found myself driving home in the dark after a fresh snowfall. The headlights catch the facets of the snowflakes, sparkling like a fairyland through the woods. This merino/silk/sparkle yarn is like that. Like a coating of fairy dust over a squishy thin strong wool/silk blend.

The first splatter dyed weft became a ringsling piece (which I realized I have no good pictures of!) and this lovely cowl. It was quite fun seeing how the weft worked up!

My second dye of the same fairy dusted yarn had smaller splatters, almost speckles, of pink and blue and purple. I take quite a lot of photos of the process of making cloth, of finished pieces of cloth both staged and in use and I quite enjoy the image-capturing process. But I think my very favorite photos to take are ones of skeins of yarn, waiting to be turned into something new. They are beautiful objects (and so textural) in and of themselves, but they're also so full of dreams and potential. Sparkle is notoriously hard to capture on camera, but you can see a hint of it here:

The draft is one that I developed by modifying an advancing point twill to create a Bethlehem Star motif. Bethlehem Star is a traditional weaving motif that you can find translated into various weave structures including overshot, double weave, and advancing twills. I loved the lace-like starry look of the pattern and felt it was appropriate for a midwinter holiday warp but couldn't find a draft that filled my needs and fit my constraints. Weaving cloth for baby wraps requires certain structural and engineering parameters are met so that it is suitable and durable for its intended weight bearing purpose. I weave on an 8 shaft loom; in general the more shafts the more complexity is possible within the patterns the loom can create. I could find 8 shaft Bethlehem Star drafts that didn't meet my structural/engineering needs and I could find Bethlehem Star drafts that required 16 or more shafts that did. But I could not find an 8 shaft Bethlehem Star draft that met my needs, so I set out to make one. I'm pretty pleased with it!

After the actual weaving is complete, once the shuttle has been thrown approximately a billionty times and the weft interlaced with the warp, the cloth is cut off of the loom. At this point it is in "loom-state" or unfinished. The true nature of the cloth doesn't come out until after wet finishing. Some handwoven fabric can be wet finished in a washer and dryer, others require more delicacy: handwashing and air drying. After wet finishing, the cloth is ironed.

Certain weaving errors (skips, some kinds of mistreadles) can be fixed after the cloth is off the loom at the same time that routine weft change yarn ends or repair threads are clipped. This can be done before or after wet finishing, or sometimes before AND after wet finishing. The more skill and practice the weaver has, and the more familiarity with one's equipment, the less need there is for this step but even the most accomplished weaver may find that the stray fix is needed. It is as time-consuming a step as any in the process, and I'm grateful to my looms, my teachers, and my years weaving that I rarely have to spend many hours at the task of mending.

Then the wrap is hemmed and tagged, middle markers are added, and children are asked to help mama model the finished product.

The same merino/silk/stellina blend weft with a slightly different dye job wove up into the baby wrap that was offered publicly for sale. It found a home with another weaver, which is SUCH a compliment!

I love how the delicate lace-like aesthetic of the weave structure meets the elegance of the skein-dyed color work to evoke the aura delicate elegance a skilled ballerina cultivates. These shades of plum and icy blue and violet encapsulate my imaginative image of what the Sugar Plum Fairy would be wearing were I to indeed meet her in the Land of Sweets. She pairs so well with ballet pink and the silver of tinsel and heirloom jewelry.

I am really pleased overall with the wrapping qualities of this particular blend of fiber and weave: thin in hand, stretchy, bouncy, comfortable on the shoulders without sag. Delightful for the squishiest wrapping of brand new humans and equally delightful for wrapping a giant toddler. I'm such a fan of cotton, wool, and silk all blended together in a textile!

As you can see here, this combination of fiber and weave created a mouldable wrap with enough grip and texture to stay solid in a half knot supporting a 25lb toddler. This blend has a high wool to silk ratio, so you get a bit of the strength and support and weightlessness of the silk without sacrificing any of the recoil and bounce of the wool that makes hiking (or snowy woods walking) such a joy.

I was able to play with some handspun weft on this warp too. This skein is in Hipstring's Unicorn Fluff color way which I spun up into yarn. It is a blend of 25% Superfine Merino wool, 25% Tussah Silk, 12.5% Mulberry Silk, 12.5% Bamboo, 12.5% Baby Camel, 12.5% Faux cashmere and is IMPOSSIBLY soft. I really appreciated the flecks of pink and blue and even aqua in this skein, it gave the finished woven piece such depth of visual character.

One of my favorite things about weaving with my own handspun is the texture. Visual texture and tactile texture. Watching handspun weave up under tension on the loom is an enormously satisfying experience. Then to pull it off the loom and experience it blooming into soft clouds of texture.... it is just so so lovely.

This particular handspun piece was auctioned as part of my on-going practice of giving back and paying forward to the world. I really treasure the opportunity to use my craft : my time, my intention, and my business to tangibly support work in the world that I believe in. The proceeds of this piece went to fund the ACLU, future handspun handwoven pieces will support other causes. Keep checking back in this space or subscribe to the newsletter to hear about donation auctions in future.

The handspun weft really made for a lovely cowl.

And that's Sugar Plum Fairy! Some warps are longer with multiple baby wraps coming off of them, and some are shorter with only one or two. I always include enough length for a small piece or three, mostly cowls as I happen to adore neckwear. Living in Alaska, warm neckwear is pretty much a necessity for most of the year! What sorts of non-babywearing items would YOU like to see from 14 Mile Farm on future warps?

Draft is a variation (of my own design) of the traditional Bethlehem Star motif

Field of Dreams

Field of Dreams is the most recent warp to come off of the loom here at 14 Mile Farm. Its woven in a "crackle" weave by Ralf Griswold. The warp is 8/2 cotton from Maurice Brassard.

This wrap was inspired by the fireweed that blooms in the Alaskan summer.

Fireweed covers the landscape here in interior Alaska in the summers. It is a very resilient plant, the first to return to area after a forest fire, hence the name. Each flower on the stalk fluffs out like a dandelion in late summer and is blown on the wind to reseed the land for the next year.

It grows on roadsides, in meadows and fields, and covers the hill in our front yard.

The warp moves through spring to summer greens, with magenta and fuschia followed by the grey blues of a late summer sky, and natty pinstriping to evoke the the fluff of the fireweed going to seed.

Here we see the cloth building up on the cloth beam. It is one of my favorite and most satisfying sights as a weaver. You can see the weft change from the magenta to the greens.

This piece is woven with a magenta Tencel, and will be staying here with us. The combination of the grippiness of the crackle weave with the glide provided by the tencel makes for divine wrapping qualities.

A cowl in grey Tencel. Tencel in a crackle weave is one of my new favorite things. I love the play between the shine of the tencel and the matte unmercerized cotton. So soft!

This piece was woven with a hand-dyed variegated Tencel weft in shades of green and will be flying to a new home.

I love the way that the variegated greens are evocative of the oh-so-green summer landscape that fireweed blooms against. This weft came together even better than I had hoped.

Bands of magenta tencel in the tails of the variegated piece to highlight the bright color of the flowering fireweed.

The variegated weft was a joy to weave, always changing. I see more hand-dyed yarns in the future here at 14 Mile Farm!